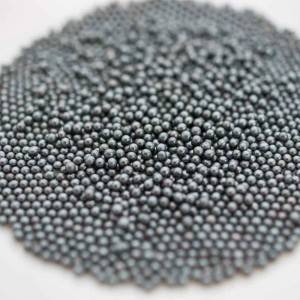

Ukuqamba ibhola lensimbi

Imodeli/Usayizi:30-150 mm

Imininingwane Yomkhiqizo:

Ibhola lokugoqa lensimbi lenziwe ngensimbi eyindilinga njengempahla eluhlaza, ecutshungulwa ngokoqobo ngobuchwepheshe obusha bokugoqa nokubunjwa bese bukhiqizwa ubuchwepheshe obukhethekile bokwelapha ukushisa.

Ngemuva kweminyaka yokuhlangenwe nakho okuqongelelwe kanye nokuhlolwa okuphindaphindiwe, kuphetha ngokuthi izinto ezifanele kakhulu zokubumba ibhola lensimbi eligoqiwe ziyi-45 #, 65Mn, 70Mn, B2 (70MnCr) njalonjalo. Yiqiniso, ezinye izimboni nazo zinezidingo ezikhethekile, inkampani yethu. ingakwazi ukwenza ngokwezifiso ukukhiqizwa ngokwezidingo zamakhasimende.

Forging steel rolling ball Izinzuzo ezine

Ukuqina okuphezuluIsikhungo sebhola HRC>46,Surface HRC56-60

Ukumelana nokugqoka okuphezuluIsakhiwo sangaphakathi sihlangene futhi okusanhlamvu kulungile

Umthelela ophezuluUkuqina komthelela kufika ku-12-35J/c㎡

UkukhathalaUkwehla kwempilo ka-6.5m izikhathi ezingama-20,000

Siqinisekisa kanjani ikhwalithi yamabhola ethu ensimbi?

01Thatha amabhilidi ekhwalithi ephezulu njengezinto zokusetshenziswa, bese udlulisela izici zensimbi ngqo kumabhola ensimbi.

Insimbi inamandla aphezulu, ukusebenza kahle okuphelele, ukumelana nokugqwala, ukumelana nokugqoka nokunye.

Izinto ezinhle

02Amathuluzi asekelayo athuthukile

Imishini esekelayo yakhelwe ongoti be-bu abavela ku-National Research Institute ukuze kuqinisekiswe ikhwalithi yokugingqika nokuhlanganisa.

03Ubuchwepheshe obuhlukile bokwelapha ukushisa

Inkampani isebenzisa izinqubo eziningi ezihlukile zokwelapha ukushisa ukuze kuqinisekiswe ubulukhuni, ukuqina kanye nokumelana nokugqoka.

Ukwelashwa kokushisa okujikelezayo

Ukwelashwa kokushisa kwamanzi

Ukwelashwa kokushisa kwe-thermal insulation

Ukucaciswa Okubalulekile:

| Ikhodi | C(%) | Si(%) | Mn(%) | Cr(%) | Cu(%) | I-Mo(%) | P(%) | S(%) | I-Ni(%) |

| 45# | 0.42-0,50 | 0.17-0.37 | 0.5-0.80 | 0-0.25 | 0-0.25 | 0-0.30 | 0-0.035 | 0-0.035 | 0-0.30 |

| 40Mn | 0.37-0.44 | 0.17-0.37 | 0.7-1.0 | 0-0.25 | 0-0.25 | 0-0.30 | 0-0.035 | 0-0.035 | 0-0.30 |

| 65Mn | 0.62-0,70 | 0.17-0.37 | 0.90-1.0 | 0-0.25 | 0-0.25 | 0-0.30 | 0-0.035 | 0-0.035 | 0-0.30 |

| 70Mn | 0.67-0,75 | 0.17-0.37 | 0.90-1.2 | 0-0.25 | 0-0.25 | 0-0.30 | 0-0.035 | 0-0.035 | 0-0.30 |

| 40Cr | 0.37-0.45 | 0.17-0.37 | 0.50-0.8 | 0.8-1.1 | 0-0.25 | 0-0.30 | 0-0.035 | 0-0.035 | 0-0.30 |

| 70Cr2 | 0.65-0,75 | 0.20-0.30 | 0.75-0.9 | 0.55-0.7 | 0-0.25 | 0-0.30 | 0-0.030 | 0-0.030 | 0-0.30 |

| B-2 | 0.70-0,80 | 0.17-0.37 | 0.70-0.8 | 0.50-0.6 | 0-0.25 | 0-0.30 | 0-0.035 | 0-0.035 | 0-0.30 |