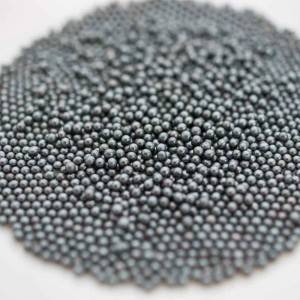

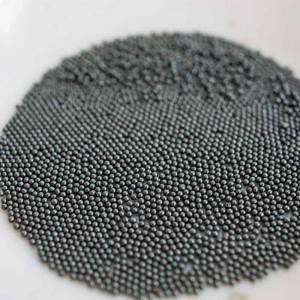

Isibhamu Sensimbi Eyindilinga Ephansi Yekhabhoni

Imodeli/Usayizi:I-S110-S930/Φ0.3mm-2.8mm

Imininingwane Yomkhiqizo:

Amashothi ensimbi ekhabhoni ephansi aqukethe ikhabhoni encane, i-phosphorus nesibabule kuneshothi yensimbi ye-carbon ephezulu.Ngakho-ke, isakhiwo esincane sangaphakathi se-low carbon shots sishelela kakhulu.Amashothi ensimbi ye-carbon steel athambile uma kuqhathaniswa namashothi ensimbi ekhabhoni ephezulu.Lokhu kuphumela ku-20 - 40 % wesikhathi eside sempilo yokugwaza.

Ukucaciswa Okubalulekile:

| PROJECT | UKUCACISWA | INDLELA YOKUHLOLA | |||

| UKWAKHIWA KWAKHEMICAL | C | 0.08-0.2% | P | ≤0.05% | ISO 9556:1989 ISO 439:1982 ISO 629:1982 ISO 10714:1992 |

|

| Si | 0.1-2.0% | Cr | / |

|

|

| Mn | 0.35-1.5% | Mo | / |

|

|

| S | ≤0.05% | Ni | / |

|

| IMICROTRUCTURE | I-Homogeneous Martensite noma i-Bainite | I-GB/T 19816.5-2005 | |||

| Ukuminyana | ≥7.0-10³kg/m³(7.0kg/dm³) | I-GB/T 19816.4-2005 | |||

| EXTERNALFORM | Imbobo yomoya < 10%.Ihlanganisa.Ikhona elicijile.Isilinganiso Sokukhubazeka< 10% | Okubonakalayo | |||

| UBUNZIMA | I-HV:390-530(HRC39.8-51.1) | I-GB/T 19816.3-2005 | |||

Izinyathelo Zokucubungula:

Scrap→Khetha&Sika→Ukuncibilika→Cwenga(khipha ikhabhoni)→Ukushisisa→Ukoma→Ukuhlola i-Scalper→Ukuphefumula nokuvuthela ukususa imbobo yomoya→Ukucisha kokuqala→Ukoma→Ukucisha→Ukushisa kwesibili→Ukupholisa→Ukuhlola Kahle→Ukupakisha Nokugcina

Izicelo:

Izindawo ezijwayelekile zokufaka isicelo: ukwelashwa kwangaphambili kwensimbi noma okusansimbi ngaphambi kokupenda, ukwehlisa nokususwa kokugqwala, ukubola.

Izinzuzo:

① Ilungele ukusetshenziswa ukunikeza indawo yensimbi ehlanzekile, ephucuziwe.

② Amashothi ensimbi ekhabhoni ephansi asetshenziswa kukho kokubili ama-turbine namasistimu okuqhuma komoya acindezelwe.Amashothi ensimbi ekhabhoni ephansi aqinisekisa ukugqokwa kwama-turbine blades aphansi.

③Umjikelezo wempilo weshothi yensimbi ye-carbon ephansi cishe ubude obungu-30% kuneshothi yensimbi ephezulu ye-carbon.

④ Inqubo yokuqhunyiswa kwesibhamu ikhiqiza uthuli oluncane, okuholela ezindlekweni eziphansi zokunakekela uhlelo lokuhlunga.

Kungani Ikhabhoni Iphansi?

Ikhabhoni ephansi nephezulu yensimbi ye-manganese inamandla okumunca umthelela omkhulu, imithelela isabalaliswa ngokufana kulo lonke ukudubula.

Ngesikhathi sokuqhunyiswa kwesibhamu, ukudubula kwensimbi ye-carbon ephansi kuyaxetshulwa phansi kube izingqimba ezincanyana ezifana nezingqimba zika-anyanisi kuze kufike kumaphesenti angu-80 wokuphila kwazo ngenxa yokuguga, futhi ziphulwa zibe izingcezu ezincane ngenxa yokukhathala kwempahla.Ukuguguleka komshini ne-blade nakho kuncishiswe kakhulu njengoba kuhlukaniswe izingxenye ezincane nezincane.

Izinhlayiya ze-carbon steel shot eziphakeme nokho ziphulwa zibe izingcezu ezinkulu nezingama-angular ngesikhathi esifushane ngenxa yesakhiwo sokuqhekeka esakhiwe ngesikhathi sokukhiqiza.Ngalesi sici, umshini ubangela izindleko ezithe xaxa emishinini ye-turbine nezihlungi.