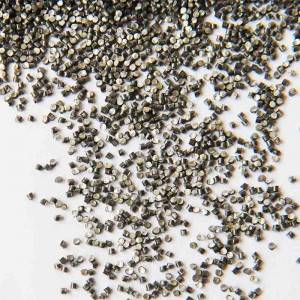

I-Carbon Angular Steel Grit ephansi

Ukucaciswa Okubalulekile:

| PROJECT | UKUCACISWA | INDLELA YOKUHLOLA | |||

| UKWAKHIWA KWAKHEMICAL | C | 0.08-0.2% | P | ≤0.05% | ISO 9556:1989 ISO 439:1982 ISO 629:1982 ISO 10714:1992 |

|

| Si | 0.1-2.0% | Cr | / |

|

|

| Mn | 0.35-1.5% | Mo | / |

|

|

| S | ≤0.05% | Ni | / |

|

| IMICROTRUCTURE | I-Homogeneous Martensite noma i-Bainite | I-GB/T 19816.5-2005 | |||

| Ukuminyana | ≥7.0-10³kg/m³(7.0kg/dm³) | I-GB/T 19816.4-2005 | |||

| EXTERNALFORM | Iphrofayili yendawo ehlanganisiwe noma eyi-angular, Imbobo yomoya < 10%. | Okubonakalayo | |||

| UBUNZIMA | I-HV:390-530(HRC39.8-51.1) | I-GB/T 19816.3-2005 | |||

Izinyathelo Zokucubungula:

Scrap→Khetha&Sika→Ukuncibilika→Cwenga(khipha ikhabhoni)→Kuyashisa→Ukoma→Ukuhlola i-Scalper→Ukuphefumula nokuvuthela ukuze kukhishwe imbobo yomoya→Ukucisha kokuqala→Ukoma→Ukucisha→Ukushisa kwesibili→Ukupholisa→Ukuphuka→Ukuhlola Kahle→Ukupakisha Nokugcina

IZINDLEKO ZOKUZUZA EZINKULU ZE-CARBON STEEL GRANAL

• Ukusebenza okungaphezu kuka-20% ngokumelene nokudutshulwa kwekhabhoni ephezulu

• Ukuncipha kokuguga kwemishini nezinto zokusebenza ngenxa yokumuncwa okukhulu kwamandla emithelela ezicucu.

• Izinhlayiya ezingenasici ezibangelwa ukwelashwa okushisayo, ukuphuka noma imifantu emincane

UKUTHUTHUKISA INDAWO

• Ukuncishiswa kwempushana

• I-Bainitic microstructure iqinisekisa ukuthi ngeke iphuke ngesikhathi sokusebenziseka kwayo

UKUBUKEKA NGOKUJWAYELEKILE

Ukuma kweshothi yensimbi ye-carbon ephansi kufana ne-spherical.Ubukhona obuncane bezinhlayiya ezinde, ezikhubazekile ezinama-pores, slag noma ukungcola kungenzeka.

Lokhu akuthinti ukusebenza kokudubula, kungaqinisekiswa ngokulinganisa ukusebenza kwayo emshinini.

UBUNZIMA

I-bainitic microstructure iqinisekisa izinga eliphezulu lokuqina.Amaphesenti angama-90 ezinhlayiyana aphakathi kuka-40 - 50 i-Rockwell C.

I-carbon ephansi ebhalansi ne-manganese iqinisekisa impilo ende ewusizo yezinhlayiya, ngaleyo ndlela ithuthukise ukuhlanzeka kwezicucu, ngoba ngomsebenzi wemishini bandisa ubulukhuni babo.

Amandla okuqhuma kwesibhamu amuncwa ikakhulukazi izingxenye, ngaleyo ndlela kunciphisa ukuguga komshini.

I-CARBON GRANULATION, UKUSEBENZA OKUPHEZULU

Ukusetshenziswa kokudubula okuphansi kwe-carbon steel kunobubanzi bemishini enamaturbines angama-2500 kuye kwangama-3000 RPM kanye nesivinini esingu-80 M/S.

Okokusebenza okusha ekusebenzisa izinjini zomoya ezingu-3600 RPM nesivinini esingu-110 M/S, lezi ziyizidingo zokwandisa umkhiqizo.