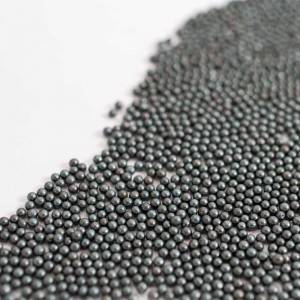

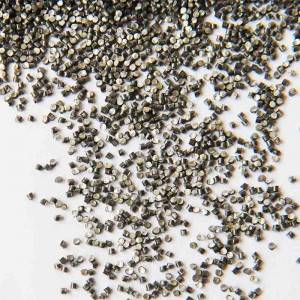

Isibhamu Esiphezulu Sensimbi Eyindilinga Yekhabhoni

Imodeli/Usayizi:I-S110-S930/Φ0.3mm-2.8mm

Imininingwane Yomkhiqizo:

I-carbon steel shot shot, eyenziwe ngensimbi ekhethekile, eqinile futhi eqinile, inokuqukethwe kwekhabhoni engaphezu kuka-0.85%.ngenqubo ye-atomization, izinhlayiya eziyindilinga ezenziwe ngensimbi encibilikisiwe.I-Fengerda ilawula ngokuqinile zonke izixhumanisi zokukhiqiza, ikakhulukazi ukulawulwa kwe-deoxidation kanye i-decarbonization, izinga lokushisa kwinqubo yokucisha, kanye nokuqedwa kwama-pores nokungavamile ngemva kokwakhiwa, okuthuthukisa umkhiqizo ezingeni elisha.

Ukucaciswa Okubalulekile:

| PROJECT | UKUCACISWA | INDLELA YOKUHLOLA | |||

| UKWAKHIWA KWAKHEMICAL |

| 0.8-1.2% | P | ≤0.05% | ISO 9556:1989 ISO 439:1982 ISO 629:1982 ISO 10714:1992 |

| Si | ≥0.4% | Cr | / | ||

| Mn | 0.35-1.2% | Mo | / | ||

| S | ≤0.05% | Ni | / | ||

| IMICROTRUCTURE | I-Homogeneous Martensite noma i-Bainite | I-GB/T 19816.5-2005 | |||

| Ukuminyana | ≥7.0*10³kg/m³(7.0kg/dm³) | I-GB/T 19816.4-2005 | |||

| EXTERNALFORM | Imbobo yomoya < 10%.Ihlanganisa.Ikhona elicijile.Isilinganiso Sokukhubazeka< 10% | Okubonakalayo | |||

| UBUNZIMA | I-HV:390-530(HRC39.8-51.1) | I-GB/T 19816.3-2005 | |||

Izinyathelo Zokucubungula:

Izinzuzo:

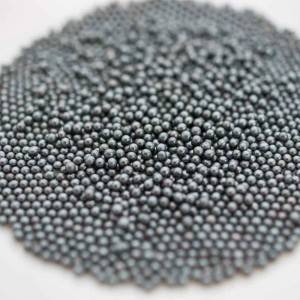

I-High Carbon Rounded Steel Shot isebenzisa indlela evamile yokukhiqiza, esetshenziselwa ukuhlanza ukuqhuma kanye nokuchama isibhamu ikakhulukazi. Ukwelashwa kokushisa okulawulwa kahle kunikeza ukuqina nokumelana nokukhathala.

futhi uqedele izingxenye zensimbi ezidinga ukukhuphuka kokugqoka nokukhathala.Kulokhu, isibhamu siqhuma ingxenye yensimbi, kwakheka ama-dimples amancane ebusweni.

Ama-dimples abangela ukucindezelwa kokucindezelwa ebusweni bengxenye, okwandisa ukumelana kwensimbi nokuqhekeka, ukukhathala, nokugqwala.I-shot peening isetshenziselwa izinto ezibalulekile, ezigqoke kakhulu njengamagiya, ama-shaft nezikhumba zensimbi emikhiqizweni ethuthukisiwe ye-aerodynamic.

Izicelo:

Isibhamu sethu se-carbon steel high sisetshenziswa ezinhlelweni ezahlukene ezifana;ukudiliza, ukwehlisa, ukuhlanza, ukuchama kwesibhamu njll. Inqubo ye-centrifugal atomization kanye nokwelashwa kokushisa okuphindwe kabili ezitshalweni ze-Airblast, kanye nokuqhubeka nezinyathelo zokulawula ikhwalithi, kuqinisekisa ukuthi ukudubula kube sezingeni eliphezulu kakhulu.

Ukuhlanzwa kokuqhuma kwe-forging, izingcezu ezishisiwe, amapayipi ensimbi, izigaba nezakhiwo zensimbi, ukulungiswa kwendawo ngaphambi kokupenda, ukupeyina kwezingcezu zomsebenzi.

Ukuhlanzwa kokuqhuma komhlaba kwamapuleti ensimbi engenasici, amapuleti ensimbi azacile, ama-alloys angeyona i-ferrous, ijazi le-dacromet.