-

Ukuthwala i-Angular Steel Grit

I-Bearing Angular Steel Grit yenziwe ngama-Bearing plates aphukile.I-bearing steel ine-Cr, i-elementi engavamile, inokusimama okuhle ngaphakathi kwesakhiwo .I-Bearing anguler steel grit inokusebenza okuzinzile okuphezulu, ukumelana nokugqoka okuphezulu, impilo yayo yokusebenza izikhathi ezingu-2.5 uma nje high-carbon steel grit kanye ne-carbin ephansi

-

I-FerroSilicon

I-Ferrosilicon iwuhlobo lwe-ferroalloy olwakhiwa ngokuncishiswa kwe-silica noma isihlabathi nge-coke lapho kukhona insimbi.Imithombo ejwayelekile ye-iron insimbi eyi-scrap noma i-millscale.Ama-Ferrosilicons anokuqukethwe kwe-silicon afika cishe ku-15% enziwa ezithandweni eziqhumayo ezifakwe izitini zomlilo ezine-asidi.

-

Cast Stainless Steel Shot

I-stainless steel shot uhlobo lwemidiya oseludume kakhulu.Le mikhiqizo yenza ngokufana nokudubula kwensimbi, nokho, yenziwe ngensimbi engagqwali.Iqukethe ukugcwala okuphezulu kwe-nickel ne-chromium.Futhi iyimithombo yezindaba enhle okufanele icatshangelwe lapho ukungcoliswa okusansimbi kocezu lomsebenzi kungenzeki

-

I-Carburizers (Izinyusi zeCarbon)

I-Carburizer, eyaziwa nangokuthi i-ejenti ye-carburizing noma i-carburant, iyisengezo ekwenzeni insimbi noma ukusakaza ukukhulisa okuqukethwe kwekhabhoni.Ama-Carburizer asetshenziselwa ukucwenga ama-Carburizer ensimbi kanye nama-Carburizers ensimbi, kanye nezinye izithasiselo kuma-Carburizers, njengezithasiselo zamabhuleki pad, njenge-friction materia.

-

I-Silicon Manganese Alloy

Ingxubevange ye-silicon manganese (i-SiMn) yenziwe nge-silicon, i-manganese, insimbi, ikhabhoni encane nezinye izakhi.Imiphumela yokwengezwa kwe-silicomanganese ensimbi: Kokubili i-silicon ne-manganese kunethonya elibalulekile ezakhiweni zensimbi.

-

I-Barium-Silicon(BaSi)

I-Ferro silicon barium inoculant iwuhlobo lwe-alloy esekelwe ku-FeSi equkethe inani elithile le-barium ne-calcium, inganciphisa ngokuphawulekayo ukugodola, ikhiqize izinsalela ezincane kakhulu.Ngakho-ke, i-Ferro silicon barium inoculant iphumelela kakhulu kune-inoculant equkethe kuphela i-calcium, esikhangisweni

-

I-Nodulizer(ReMgSiFe)

I-Nodulizer iwumlutha ongakhuthaza ukwakheka kwe-spheroidal graphite kusuka kuzingcezu zegraphite ezinqubweni zokukhiqiza.Ingathuthukisa ama-graphite angama-spheroidal futhi ikhulise inani lama-spheroidal graphite ukuze izakhiwo zawo zemishini zithuthukiswe.Ngenxa yalokho, i-ductility nokuqina

-

I-Strontium-Silicon(SrSi)

I-Ferro silicon strontium nucleating agent iwuhlobo lwe-alloy esekelwe ku-FeSi equkethe inani elithile le-barium ne-calcium, inganciphisa ngokuphawulekayo into ebandayo, ikhiqize izinsalela ezincane kakhulu.Ngakho-ke, i-Ferro silicon barium inoculant iphumelela kakhulu kune-inoculant equkethe i-calc kuphela

-

I-Calcium-Silicon(CaSi)

I-Silicon Calcium Deoxidizer yakhiwa izakhi ze-silicon, i-calcium nensimbi, iyi-deoxidizer ehlanganisiwe efanelekile, i-ejenti ye-desulfurization.Isetshenziswa kabanzi ensimbi yekhwalithi ephezulu, insimbi ephansi ye-carbon, ukukhiqizwa kwensimbi engagqwali kanye ne-nickel base alloy, i-titanium alloy nokunye ukukhiqizwa okukhethekile kwe-alloy.

-

I-Magnesium-Silicon (MgSi)

I-Ferro silicon magnesium Nodulizer ihlanganisa kabusha ingxubevange ehlanganisa umhlaba ongavamile, i-magnesium, i-silicon ne-calcium.I-Ferro silicon magnesium nodulizer iyi-nodulizer enhle kakhulu enomphumela oqinile we-deoxidation kanye ne-desulfurization.I-Ferrosilicon, i-Ce+La mish metal noma i-ferrosilicon yomhlaba engavamile kanye ne-magnesium kukhona

-

I-FerroManganese

I-Ferromanganese iwuhlobo lwe-ferroalloy olwakhiwe ngensimbi ne-manganese.yenziwa ngokushisisa ingxube yama-oxides MnO2 kanye ne-Fe2O3, nge-carbon, ngokuvamile njengamalahle ne-coke, kuhhavini eliqhumayo noma ohlelweni lomlilo we-arc kagesi, ebizwa ngokuthi isithando somlilo esingaphansi kwamanzi.

-

I-FerroChrome

I-Ferrochrome (FeCr) iyingxubevange ye-chromium nensimbi equkethe phakathi kuka-50% no-70% we-chromium.Ngaphezu kwama-80% e-ferrochrome yomhlaba asetshenziswa ekukhiqizeni insimbi engagqwali.Ngokusho kokuqukethwe kwekhabhoni, ingahlukaniswa ngokuthi:Ikhabhoni ephezulu ye-ferrochrome/HCFeCr(C:4% -8%),i-carbon ferrochrome/MCFeCr(C:1% -4%),i-carbon ferrochrome/LCFeCr(C:0.25) %-0.5%),I-Micro carbon ferrochrome/MCFeCr:(C:0.03-0.15%).I-China ngokukhuphula ingxenye yokukhiqizwa kwe-ferrochrome emhlabeni.

-

UFerro Molybdenum

I-Ferromolybdenum iyi-ferroalloy eyakhiwe nge-molybdenum ne-iron, ngokuvamile equkethe i-molybdenum 50~60%, esetshenziswa njengesengezo sengxubevange ekwenzeni insimbi.Isetshenziswa kakhulu ekwenzeni insimbi njengesithako se-molybdenum. ikristalu elihle

-

I-Stainless Steel Cut Wire Shot

Insimbi engagqwali cut wire shot is specialty yethu ethile.Yenziwe ngochungechunge lwe-SUS200, 300, 400 lwezintambo zensimbi engagqwali ezisikwe zibe izingxenye.Insimbi engagqwali cut wire shot isetshenziswa enanini elandayo lezinhlelo zokusebenza ezibalulekile lapho ukungcola okusansimbi ekuqhunyisweni kwensimbi engagqwali, titanium.

-

Forged Stainless Steel Shot

Isibhamu sensimbi engagqwali ye-Forged senziwa nge-SUS200, 300, 400 series steel stainless steel futhi yagaywa yaba amabhola anendilinga ehlukene.

-

Isibhamu Esiphezulu Sensimbi Eyindilinga Yekhabhoni

I-carbon steel shot shot, eyenziwe ngensimbi ekhethekile, eqinile futhi eqinile, inokuqukethwe kwekhabhoni engaphezu kuka-0.85%.ngenqubo ye-atomization, izinhlayiya eziyindilinga ezenziwe ngensimbi encibilikisiwe.I-Fengerda ilawula ngokuqinile zonke izixhumanisi zokukhiqiza, ikakhulukazi ukulawulwa kwe-deoxidation kanye i-decarboniza

-

Isibhamu Sensimbi Eyindilinga Ephansi Yekhabhoni

Amashothi ensimbi ekhabhoni ephansi aqukethe ikhabhoni encane, i-phosphorus nesibabule kuneshothi yensimbi ye-carbon ephezulu.Ngakho-ke, isakhiwo esincane sangaphakathi se-low carbon shots sishelela kakhulu.Amashothi ensimbi ye-carbon steel athambile uma kuqhathaniswa namashothi ensimbi ekhabhoni ephezulu.

-

I-Aluminium shot/cut wire shot

I-Aluminium cut-wire shot (i-Aluminium Shot) itholakala ngamamaki e-aluminium axutshwe (4043, 5053) kanye namamaki e-alloy afana nohlobo 5356. Amabanga ethu axubile aveza ububanzi obuphakathi B (Cishe 40) ubulukhuni be-Rockwell kuyilapho uhlobo 5356 luzokhiqiza i-Rockwell ephezulu. B ubulukhuni ebangeni lama-50 kuye kwangama-70.

-

I-Red Copper shot/copper cut wire shot

1. Isusa ukukhanya kufikela ku-0.20″ ekulingiseni ngaphandle kokulimaza indawo engaphezulu

Yehlisa ukuguga nokuwohloka kwemishini yokuqhuma

Isusa upende nokunye okokunamathela ngaphandle kokulimaza indawo engaphezulu

Ifilimu elizacile le-zinc lifakwa ezingxenyeni zensimbi phakathi nomjikelezo ohlinzeka ngokuvikela ukugqwala kwesikhashana -

Zinc shot/Zinc cut wire shot

Sinikeza uhla lwekhwalithi lweZinc Cut Wire Shots.Itholakala ngamanani afanelekile, imikhiqizo yethu yehlisa ukuguga nokuguga emishinini yokuqhuma.Lezi zithombe ze-Zinc cut wire zithambile kunocingo olusikiwe lwensimbi engagqwali noma imikhiqizo ephonswe.I-Zinc cut wire shot itholakala ngosayizi abahlukene.

-

Ukugaya Steel Shot

Insimbi yokugaya ingxubevange isekelwe ekudubuleni kwensimbi enekhabhoni ephezulu, isibhamu sensimbi enekhabhoni ephansi, kanye nesibhamu sensimbi esiphansi se-vanadium, uma kucatshangelwa ubuthakathaka obubulalayo bale mikhiqizo engenhla: imbobo yomoya, imifantu, umehluko wokuqina, thuthukisa imikhiqizo emisha ngokucwaninga kabusha ubuchwepheshe bokuqamba, bungakhetha izinto ezahlukahlukene

-

Ukuqamba ibhola lensimbi

Ibhola lokugoqa lensimbi lenziwe ngensimbi eyindilinga njengempahla eluhlaza, ecutshungulwa ngokomzimba ngobuchwepheshe obusha bokugoqa kanye nokubumba bese bukhiqizwa ubuchwepheshe obukhethekile bokwelapha ukushisa.

Ngemuva kweminyaka yokuhlangenwe nakho kokuqongelela nokuhlolwa okuphindaphindiwe, -

Sika I-wire Shot/Intambo Entsha

I-Cut Wire Shot ikhiqizwa ngocingo lwekhwalithi ephezulu olusikwa lube ubude obulingana nobubanzi bayo.Intambo esetshenziselwa ukukhiqiza i-Cut Wire Shot ingenziwa nge-Carbon Steel, i-Stainless Steel, i-Aluminium, i-Zinc, i-Nickel Alloy, i-Copper noma amanye ama-alloys ensimbi.Isenamakhona acijile ukusuka ekusikeni

-

Sika i-Wire Shot/Intambo Esetshenzisiwe

I-recycled steel cut wire shot iwuhlobo lomkhiqizo osebenzisa izinto ezigaywe kabusha, izindleko zayo zempahla ziphansi, futhi kunzima ukukhiqiza imikhiqizo enembayo ephezulu, lolu hlobo lomkhiqizo lungasetshenziswa kuphela ukuhlanza indawo ekhonjiwe. Isetshenziswa kakhulu emphakathini izindawo.Kumakhasimende angenawo akhethekile

-

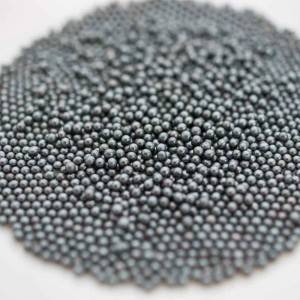

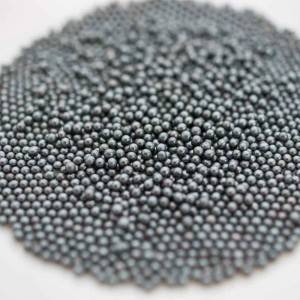

High Carbon Angular Steel Grit

Insimbi ephezulu ye-angular steel grit ikhiqizwa ngeshothi yensimbi ye-carbon ephezulu.Amashothi ensimbi achotshozwa abe yizinhlayiyana zenhlanzi futhi kamuva afuthelwe abe ubulukhuni obuthathu obuhlukene (GH, GL kanye ne-GP) ukuze kuhlinzekelwe izinhlelo zokusebenza ezahlukene.High carbon steel grit isetshenziswa kabanzi njengendlela media for descali

-

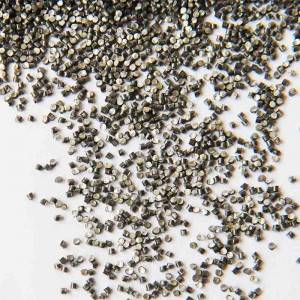

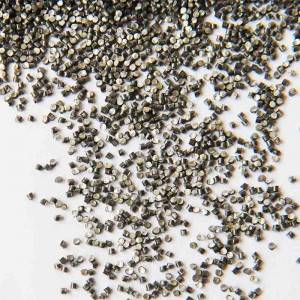

I-Carbon Angular Steel Grit ephansi

Insimbi ene-carbon angular grit yenziwa ngensimbi ye-carbon steel

shot.Izithombe zensimbi ezichotshozwa zibe yizinhlayiya zezinhlayiya.Azinasici ngenxa yokwelashwa okushisa njengoba ukwelashwa okwengeziwe akudingekile.

- Ucingo

- 0086-632-5985228

- I-imeyili

- info@fengerda.com